High Voltage & Modular

VESCAT HighVolt

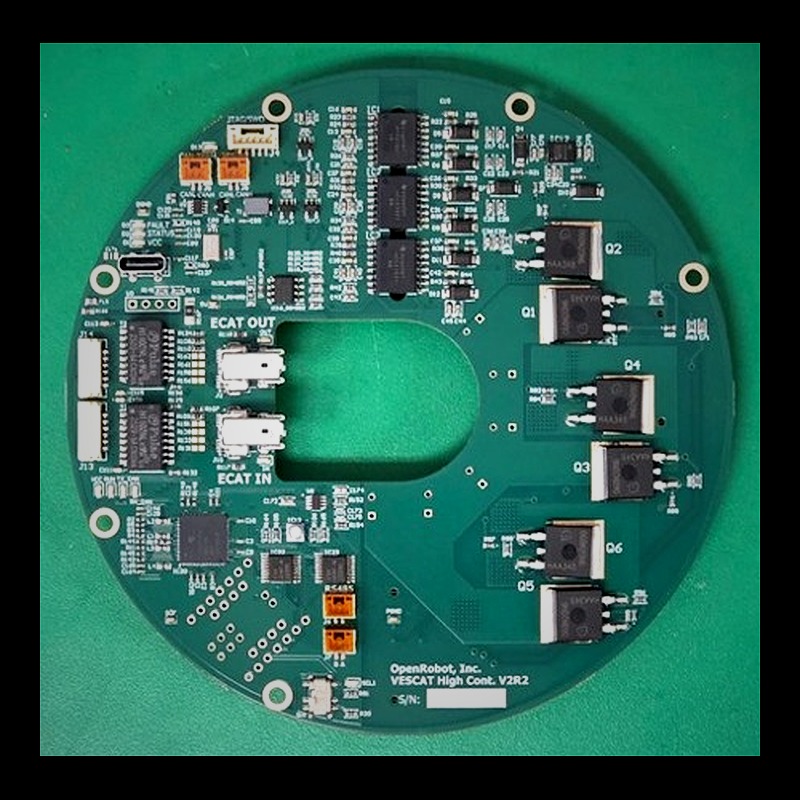

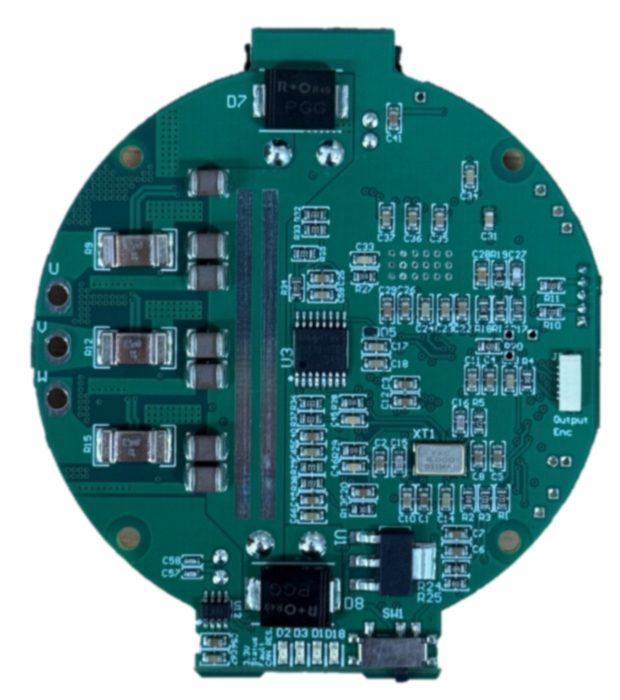

Stacked modular architecture — Power Board + Controller Board

VESCAT HighVolt is a high-efficiency modular motor controller designed for high-voltage actuator systems. By operating at high voltage, it significantly reduces current draw and heat generation while achieving superior efficiency — enabling compact, thermally stable designs for demanding applications. Its two-layer stacked architecture separates the Power Board and Controller Board for maximum scalability, and built-in EtherCAT support enables real-time, high-speed communication for multi-axis industrial and robotic systems.

160 VDC

Rated Voltage (200 VDC max)

1kW

Peak Power

SPI Encoder

e.g. RLS AksIM-2

CAN / EtherCAT

Communication Interfaces

- High-voltage drive — lower current, less heat, higher efficiency

- EtherCAT real-time communication for multi-axis control

- 2-layer stacked design (Power Board + Controller Board)

- PCB conformal coating for moisture resistance

- CAN bus communication support